When you plan a cargo bike project—whether for a private label, a fleet, or a public mobility program—the frame is not just a component.

It is the foundation that defines safety, durability, compliance, scalability, and long-term operating cost.

This article explains what makes a cargo bike frame fundamentally different from a standard ebike frame, how to evaluate materials, regulations, and design choices, and how you can assess whether a manufacturer is truly capable of delivering compliant, customizable cargo bicycles at scale.

Why Is a Cargo Bike Frame Not Just a Bigger Ebike Frame?

Short answer: because cargo bikes are load-bearing utility vehicles, not personal mobility products.

A standard ebike electric bike frame is designed around:

- One rider

- Short, dynamic loads

- Limited structural stress cycles

A cargo bike frame must handle:

- Static and dynamic loads (children, goods, containers)

- Asymmetrical weight distribution

- Frequent stops, starts, and curb impacts

- Long service life under daily use

In engineering terms, cargo frames require:

- Higher fatigue resistance

- Reinforced joints and welds

- Different tube profiles and thickness

- Load-specific geometry

This is why simply scaling an ebike alloy frame is not enough—and why many “cargo” models fail in long-term testing.

What Materials Are Used for Cargo Bike Frames—and Why?

Material choice defines both performance and compliance.

Common Cargo Bike Frame Materials

| Material | Typical Use | Key Advantages | Trade-offs |

|---|---|---|---|

| Aluminum alloy frame (6061 / 7005) | Most EU cargo bikes | Lightweight, corrosion-resistant, scalable | Requires precise welding & heat treatment |

| High-strength steel | Freight bicycle, heavy-duty trike | Excellent fatigue resistance | Heavier, higher logistics cost |

| Chromoly steel | Custom utility bicycle | Ride comfort, repairable | Limited mass production |

| Composite (rare) | Experimental | Weight reduction | Cost, regulation complexity |

For most European markets, aluminum alloy frames dominate because they balance:

- Structural strength

- Weight efficiency

- Cost control

- Regulation compatibility

However, not every factory that builds ebike framesets can manufacture aluminum cargo frames correctly. Wall thickness, joint geometry, and welding sequence all change.

Which EU Regulations Apply to Cargo Bike Frames?

If your target market is Europe, compliance is non-negotiable.

Key EU Standards & Policies

- EN 17860 – Cargo bike structural safety (static & dynamic load tests)

- EN 15194 – EPAC electrical system requirements

- EN ISO 4210 – Bicycle safety requirements

- Machinery Directive (for commercial use cases)

- Local municipal procurement rules (public fleets)

For a three-wheeled cargo bike or freight tricycle, load testing thresholds are significantly higher than for two-wheeled models.

Important:

A factory that can legally produce ebikes is not automatically qualified to produce compliant cargo bikes.

Ask this directly:

“Have your cargo frames passed EN 17860 testing under full rated load?”

How Frame Design Changes by Cargo Bike Type

Not all cargo bicycles load stress the same way.

Cargo Bike Frame Architecture — Engineering Overview Table

| Structural Type | Wheel Configuration | Primary Load Path | Key Frame Focus | Common Engineering Risks |

|---|---|---|---|---|

| Front-loading cargo bike (long john) | two-wheeled | front axle → head tube → down tube | torsional stiffness, head tube reinforcement, steering linkage alignment | frame flex, unstable steering, fatigue at head tube junction |

| Rear-loading cargo bike (longtail / midtail) | two-wheeled | rear axle → rear triangle → seat tube | rear triangle strength, dropout accuracy, fatigue resistance | rear sway under load, cracking at chainstay–seat tube |

| Front-loading cargo trike | three-wheeled (2F+1R) | cargo box → front cross-member → main frame | cross-member rigidity, load symmetry, frame–box integration | uneven cornering load, heavy steering, frame twist |

| Rear-loading cargo trike | three-wheeled (1F+2R) | rear platform → rear subframe → main frame | static load capacity, axle mounting precision, long-term stress resistance | rear sag, low durability in stop–start use |

Designing a frameset without understanding these differences leads to overbuilt or underperforming products.

If you are planning a cargo bike program and want to validate whether a frame concept is structurally viable for your target use case, it is worth discussing the architecture before locking components or tooling.

Turning Radius and Cargo Box Fit

For cargo bikes, frame design defines more than strength.

It directly affects turning radius and low-speed control, which are critical in urban use.

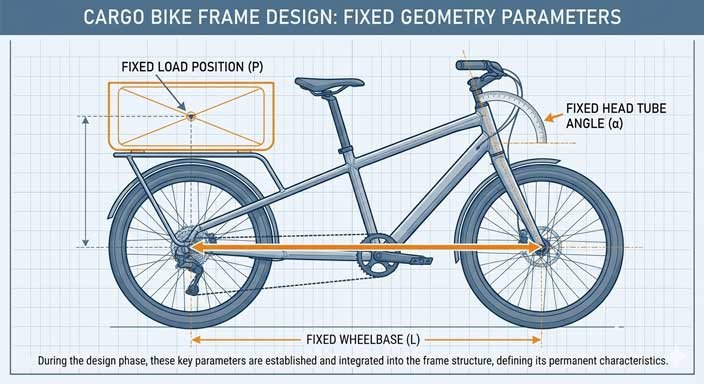

Wheelbase, head tube angle, and load position are fixed at the frame level. If these are not designed around real city conditions, even a strong frame can feel hard to manoeuvre—especially when fully loaded.

Cargo box dimensions must also be defined early. Box length, width, and mounting position influence steering clearance, weight distribution, and front-end stress. Treating the box as an add-on often leads to poor handling.

For front loaders, longtail frames, and three-wheeled cargo bikes, the frame and box should be designed as one system to ensure predictable turning and everyday usability.

How the Frame Must Match Other Key Components

A cargo bike frame does not work in isolation.

Critical matching points:

- Brake system: hydraulic disc brakes require mounting rigidity

- Mid-drive motor: torque transfer affects bottom bracket design

- Electric bike battery: mounting position impacts center of gravity

- Axles & wheels: frame spacing must match load-rated wheels

Poor matching creates noise, premature wear, or unsafe handling.

What Does a Proper Cargo Bike Development Process Look Like?

If you plan a custom cargo bike project, this is the standard process you should expect:

- Use-case definition (family, logistics, fleet, public service)

- Load & lifecycle analysis

- Frame concept & geometry validation

- Material & welding process selection

- Prototype & fatigue testing

- Regulation testing (EU standards)

- Pilot production

- SOP-based mass production

If a supplier skips steps, the risk transfers to you.

How to Evaluate a Cargo Bike Manufacturer (Practical Checklist)

When sourcing a cargo bike manufacturer, ask questions you can verify:

- Do you have EN 17860 test reports for cargo frames?

- Do you manufacture cargo-specific aluminum alloy frames in-house?

- How do you control weld consistency?

- Can you adapt frame geometry, not just paint or parts?

- Do you have SOPs for frame inspection and fatigue testing?

- Have you delivered to fleets or public projects before?

Request process evidence, not promises.

How to Communicate Your Market Needs Clearly

To get the right frame, describe:

- Target load (kg, dynamic vs static)

- Daily usage frequency

- Storage & parking conditions

- Local regulations

- Climate exposure

- Maintenance capability of end users

Clear input leads to a frame that works in reality—not just on paper.

Thinking About a Custom Cargo Bike Project?

If you are developing a cargo bike wholesale, private label, or fleet-specific model, the frame decision will define your product’s success more than any single component.

At UM, we support cargo bike ODM projects with:

- Nearly 20 years of frame development experience

- EU regulation expertise

- Certified testing processes

- SOP-driven, scalable production

- Flexible customization beyond cosmetics

If you want to discuss your use case, market, or technical requirements, you can contact us for a professional evaluation and quotation—no pressure, just informed guidance.

Final Thought

A cargo bike frame is not where you cut corners.

It is where you build trust, longevity, and real-world value.

Contate-nos for a customized cargo bike frame design solution.