As a B2B partner in the European electric cargo bike industry, trust and reliability are paramount. Your business depends on durability to ensure uninterrupted daily logistics, making cargo bike frame integrity of utmost importance. With over 16 years of experience as a leading cargo bike manufacturer, we design frames engineered to withstand the toughest operational demands—backed by rigorous science, certified testing, and compliance with strict EU standards.

Here’s how we ensure our frames deliver unbreakable performance that lets your business thrive.

The Core Concern: Frame Breakage & How We Eliminate It

Frame breakage usually stems from three issues: poor material choice, inadequate design, or insufficient testing. At our facility, we tackle all three with a methodical, data-driven approach.

Whether you’re a distributor, wholesaler, or brand looking for ODM e-cargo bike supplier solutions, understanding how we build trust into every frame can help you reassure your customers—and reduce returns, warranties, and safety concerns.

1. Material Matters: Picking the Right Metal for the Job

Not all cargo bikes are built the same. We match materials to use-cases—because a bike carrying 200kg of goods needs a different build than one used for light urban deliveries.

Here’s how we do it:

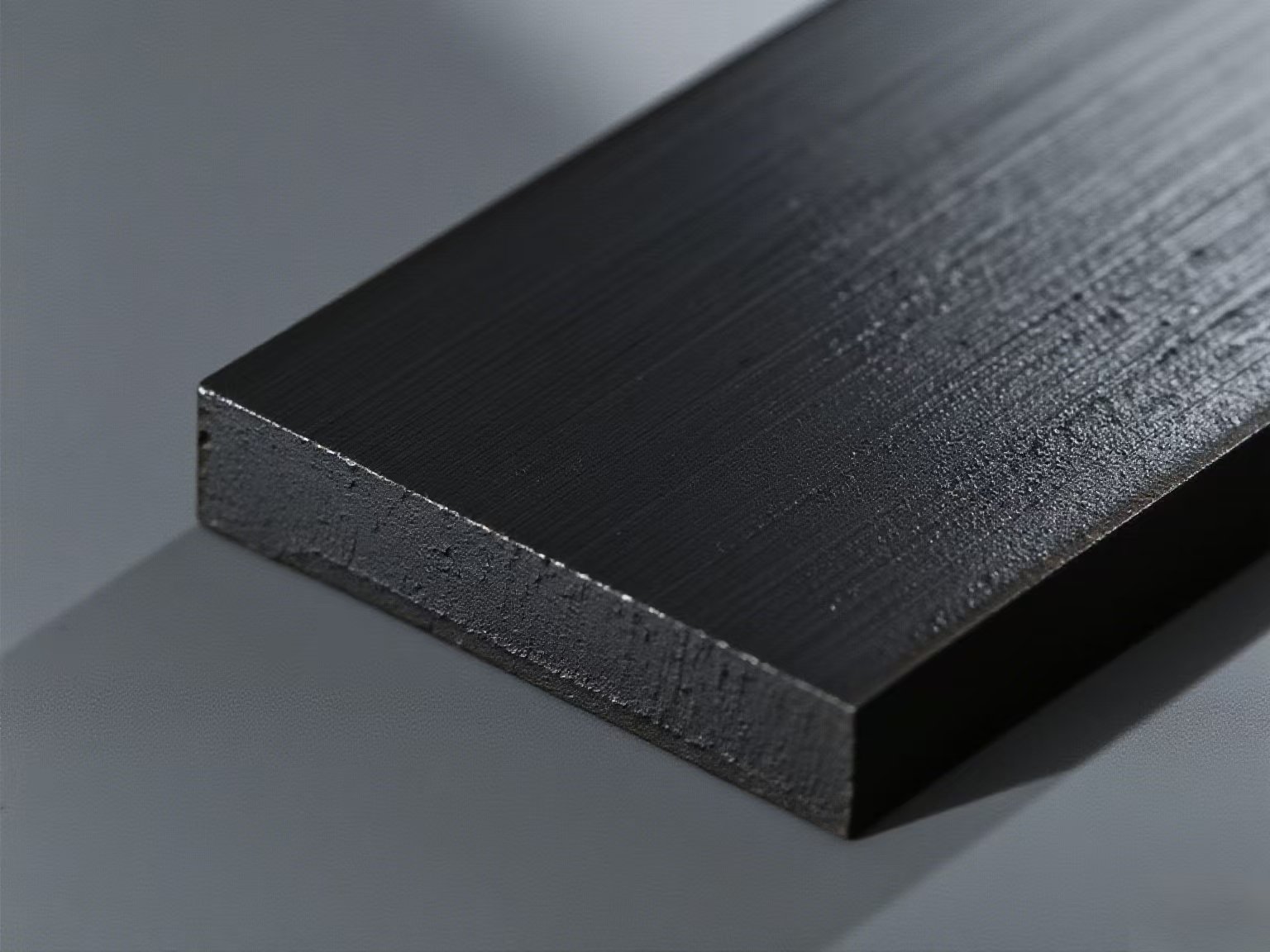

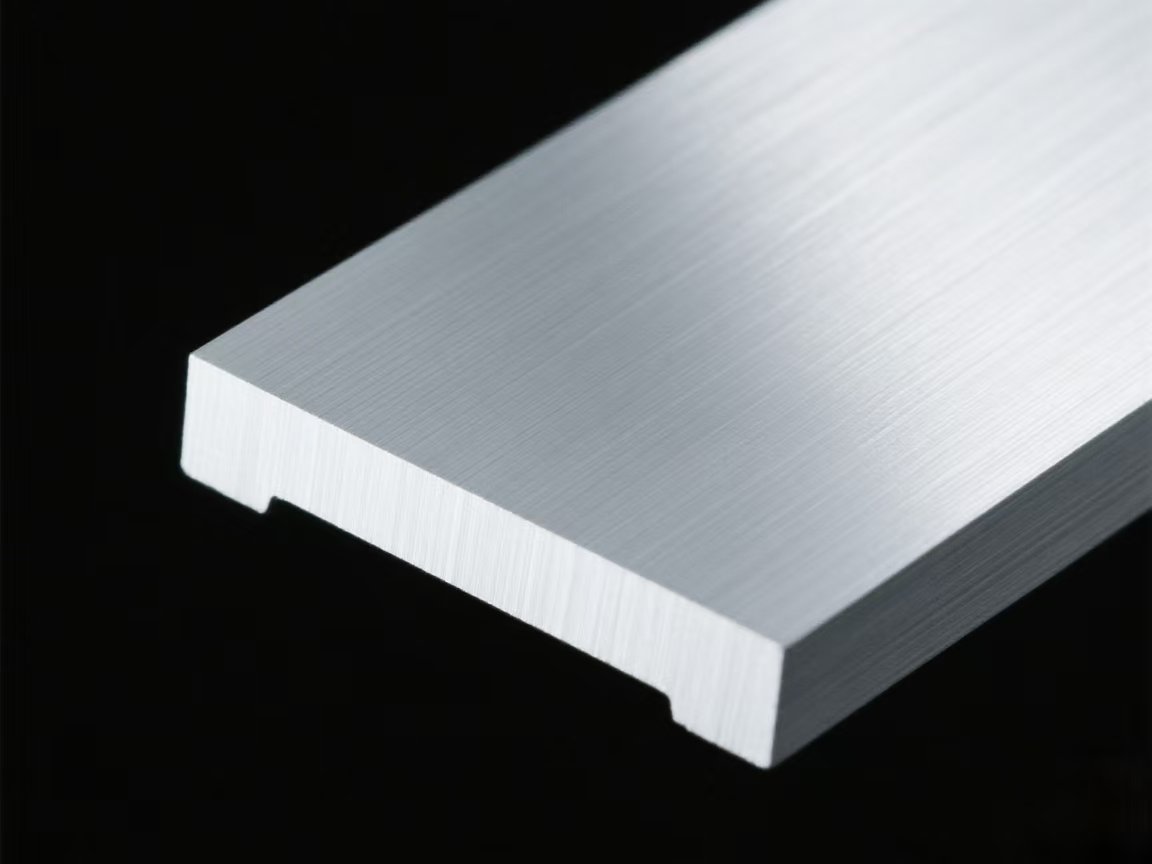

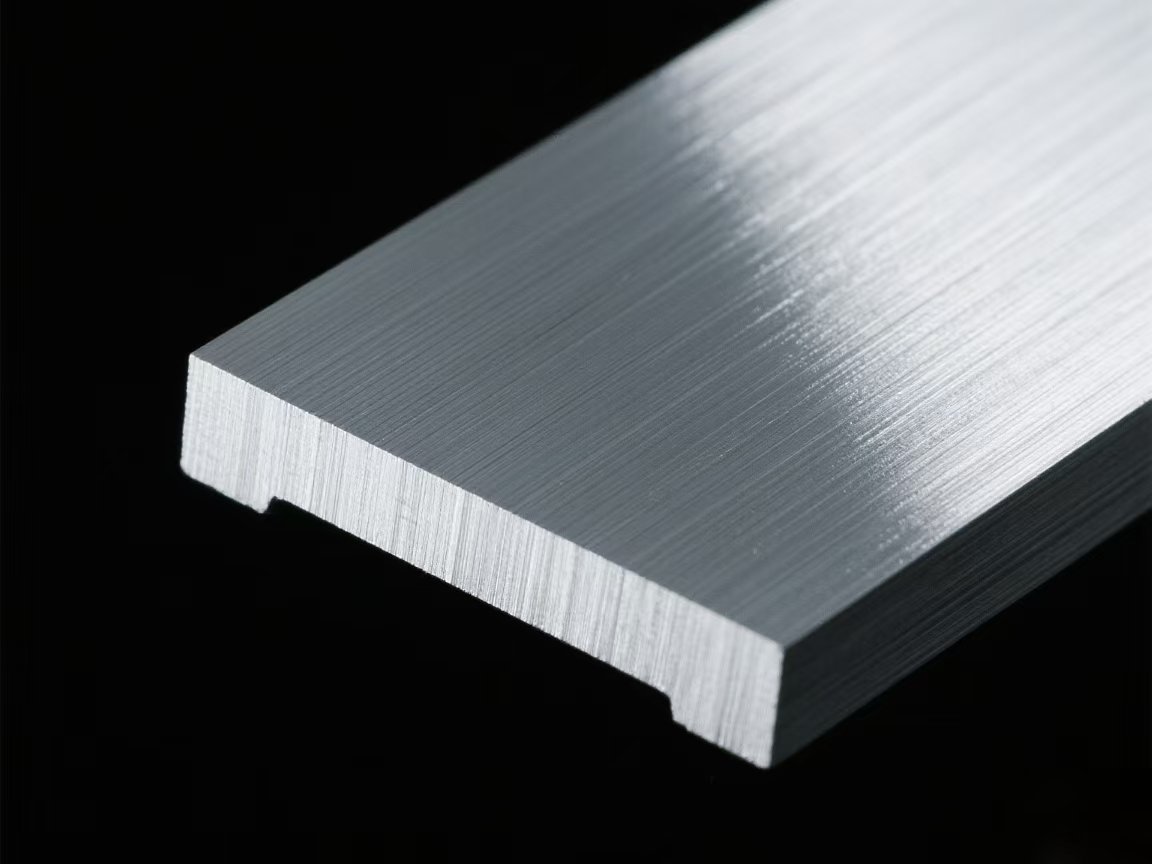

- For Everyday Use & Mid-Loads: Carbon Structural Steel (Q235)

Affordable, reliable, and tough. With a yield strength of ≥235 MPa and excellent elongation (≥26%), it absorbs shocks and resists deformation. Think of it like the dependable work truck—built to last. - For Lightweight & Agile Delivery Fleets: Advanced Aluminium Alloy (6061-T6 & 7075)

Ideal for brands targeting eco-conscious consumers or last-mile delivery teams. These alloys are up to 30% lighter than steel, boosting battery range and handling. The 7075 variant offers tensile strength up to 580 MPa—comparable to some steels—but at a fraction of the weight. - For Heavy-Duty, Industrial Applications: Chromoly Steel (30CrMo)

When your customers need to move serious weight—≥200kg, often on rough terrain—we turn to chromium-molybdenum steel. With a tensile strength ≥980 MPa and high impact resistance, it’s the backbone of industrial-grade custom electric bikes.

More reading: A Review of the Cargo Bike Frame Collapse Crisis

Comparison Table: Key Material Properties

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Elongation (%) |

|---|---|---|---|---|

| Q235 Steel | 375–500 | ≥235 | 7.85 | ≥26 |

| 6061-T6 Aluminum | 260–350 | ≥240 | 2.7 | ≥10 |

| 7075 Aluminum | 500–580 | ≥430 | 2.8 | ≥8 |

| 30CrMo Chromoly | ≥980 | ≥785 | 7.85 | ≥12 |

This comparison makes it clear: each material serves a different business case. From affordable everyday fleets to high-end custom electric bike builds, we ensure the right balance between weight, strength, and cost.

2. Engineering Precision: Virtual Testing to Eliminate Weakness

Picking strong materials is only half the battle. How they’re shaped and joined matters just as much.

Using CAE (Computer-Aided Engineering), we simulate real-world stresses—static loads, vibrations, and impacts digitally—before creating a prototype. It’s like doing a crash test in a virtual lab.

We analyse:

- Static load capacity

- Fatigue life under repeated stress

- Vibration and resonance behaviour

- Shock absorption in collision scenarios

This virtual crash testing lets us design out weak points early, shortening lead times and guaranteeing frames that perform right from the first ride.

3. Certified Strength: Exceeding EU Standards for Commercial Use

Simulations are great—but real-world validation is irreplaceable. That’s why we subject every cargo bike frame to brutal testing cycles that go beyond EU norms.

All tests are based on EN 17860—the latest European standard for cargo bikes—but we often exceed them, especially for commercial use.

Here’s what that looks like:

- 200,000+ Pedal Force Cycles

- 200,000+ Horizontal Force Cycles

- 50,000+ Vertical Load Cycles

- 200,000+ Load Area Tests

- 200,000+ Lateral Force Tests

Plus, we run environmental simulations including salt spray tests (≥72 hours) and thermal cycling (-40°C to +60°C) to ensure longevity and reliability even in harsh climates and heavy commercial use.

4. Real-World Validation: Over 1,000 Kilometres of Rugged Terrain Testing

Lab tests are controlled—but the real world isn’t. So we take our bikes out on mixed terrains:

- 30% paved city roads

- 30% gravel and unpaved paths

- 20% inclines (up to 18% gradient)

- 20% obstacle testing (curbs, potholes, etc.)

We test under uneven loading, dynamic shifts, and full payloads—because how a bike performs when poorly loaded says everything about its safety.

5. Trusted Certification: TÜV Rheinland and EN 17860 Compliance

Finally, we send random samples to TÜV Rheinland—Germany’s leading independent certifier. They test everything from mechanical strength to electrical safety and factory processes. Our independent TÜV Rheinland certification is your guarantee that frames meet the highest European mechanical and electrical safety standards.

Only after passing all checks do we receive the EN 17860 certificate—proof that our electric cargo bikes meet the highest European standards for both private and commercial use.

More information of EN 17860 which you need to know as a cargobike brand

Why Choose Us as Your EU ODM Cargo E-Bike Supplier?

When you partner with us as your ODM cargo bike supplier with custom branding, you’re not just buying bikes—you’re buying peace of mind.

You benefit from:

- European-Standard Compliant frames built in audited factories using globally sourced premium materials

- Flexibility with full customisation from frame geometry to branding tailored to your market

- Local warehouse support in key EU regions for faster delivery and service turnaround

- Decades of engineering expertise paired with proven commercial durability

You maybe interested in: Sourcing & OEM Guide on Start Your Custom Cargo Bike Business in Europe

Conclusion: Frame Strength Isn’t a Guess—It’s a Guarantee

We know that cargo bike frame failure is a real concern. But through rigorous material selection, engineering-led design, extreme testing, and third-party certification, we build frames that you—and your customers—can trust.

Whether you’re looking for wholesale cargo bike options or fully custom electric bike solutions, we offer the technical foundation and quality assurance to help your brand stand out.

Ready to offer your clients unbreakable quality and unmatched reliability?

Contáctanos today to discuss your tailored ODM e-cargo bike project and partner with a supplier that carries your trust every mile.

More reading:

Complete Guide to Cargo E-Bikes: An Industry Reference

Insights from E Cargo Bike Experts: Safety, Design & Market Trends